1

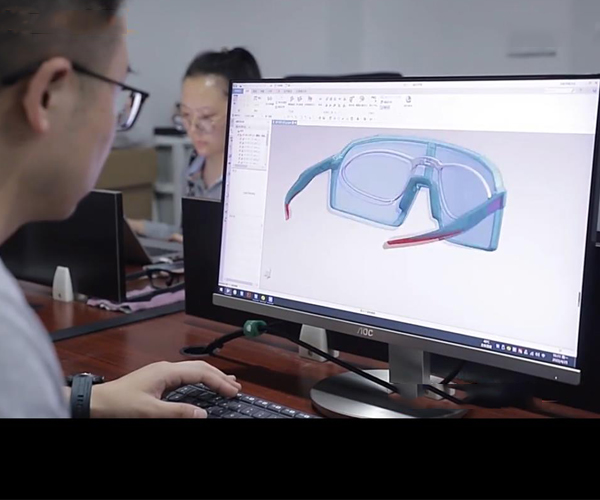

Pre-Production:3D moulding Drawing

Provide design ideas, somta designs and develops the product mold according to the agreed time. Our R&D team will consider all customers' requirements and complete drawings within 1 hour and samples within 7 days.

1.Offer your idea about the sunglasses

2.Draw a picture

3.3D Moulding

4.Confirm design draft

2

Lenses Production

In this progress, we produce high-end lenses such as photochromic lenses, polycarbonate lenses, tac polarized lenses, pc polarized lenses, etc., as well as multi-functional smart lenses with ultra-long-lasting anti-fog, anti-UV, etc

1. Quality inspection of incoming lenses

2. Cutting the lenses

3. Lens logo printing

3

Frame Production

In this process, frames are made with the raw materials on a mold that is loaded on the injection-molding machine

1. Frame injucting

2. Spray paint

3. Polishing

4

Logo Design

In this process, we open the steel mold according to the customer's label style, and print, laser, UV embossed and other styles according to the customer's requirements.

1. Creat logo mouding

2. Printing logo/laser logo/UV embossed logo as your request

4

Assemble and Packing

In this process, we assemble the lenses and frames with logos into glasses, and pack them in the packaging box with lens cloth, lens bags, spare lenses and instructions, and attach barcodes or box marks according to customer packaging requirements.

1. Locking temple screws

2. Attach the lens to the frame

3. Check whether the temple leg are high or low

4. Packing